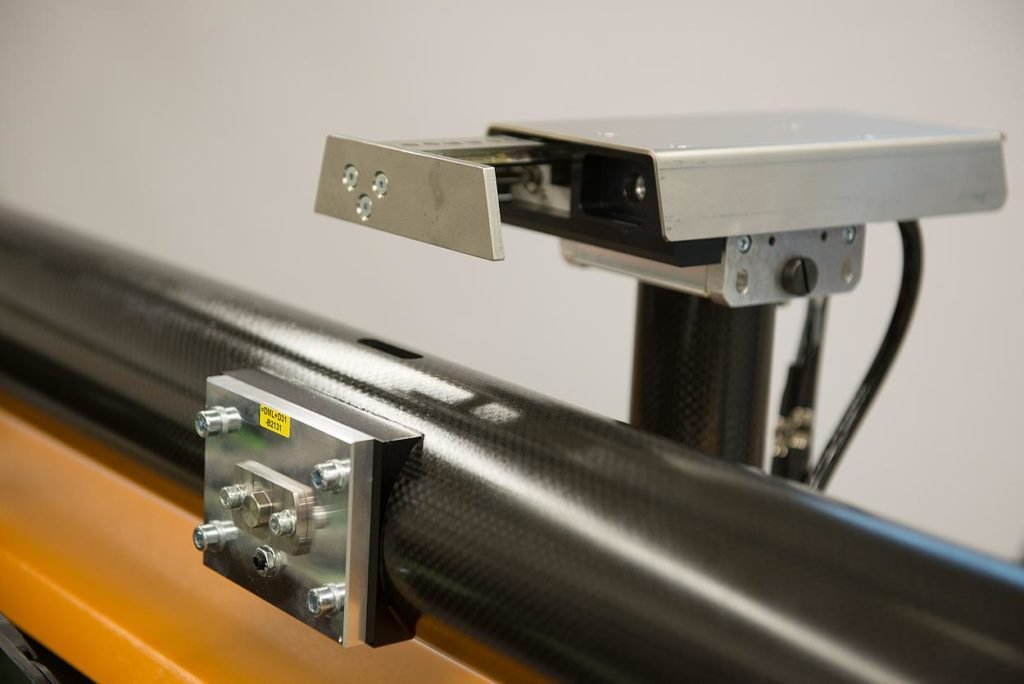

GreCon DML 6000

Contactless inline thickness measurement with laser technology

The Thickness Gauge DML 6000 measures the material thickness of solid, soft and humid materials by contactless measuring using laser beams. The measured values can be taken to the very edge of the material. Depending on the requirements, measurements can be made at stationary points or traversing across the whole production width. Traverse measurement allows measurement of a maximum amount of material and clearly shows any linear deformation of the material.

BENEFITS AT A GLANCE

MEASURING METHOD

The Thickness Gauge DML measures the material thickness of solid, soft and humid materials by contactless measuring using laser beams.

In terms of the measuring principle, measurement against precision rollers is distinguished from difference measurement. When measuring against precision rollers, the material is scanned only from one side and a roller is on the opposite side corresponding to the zero line. The difference measurement determines the thickness of the material by scanning on both sides and calculating both values. The thickness is calculated by triangulation. A laser beam is sent to the material surface and observed by a camera provided beside it. If the distance to the board changes, the observation angle changes too and consequently also the position of the image in the sensor is different. The distance to the measured value can be calculated based on the position of the image. Individual measured values determine the material thickness by offsetting.

Afterwards, every measuring track is shown with the measured value in a graphic on a screen.

The production can be adapted to material saving.

Calibration

The DML 6000 is equipped with a calibration test function. Calibration is done below the production level and ensures consistent measuring accuracy.

SOFTWARE FUNCTIONS AND VISUALISATION

APPLICATION

TECHNICAL DATA