GreCon EASYLOG+

BENEFITS AT A GLANCE

-

- Information on the glue hardening in the panel (reaching of the threshold of 100 °C at every position)

- Optimization of the existing press programs

- Recognition of influences of upstream and downstream processes

- For panels of a thickness of more than 10 mm

- Measurement of the steam pressure

- Short commissioning of the wood based panel production

- Recipe adaptations in record time.

- Low construction height (2.5 mm)

- Temperature measurements during cooling, conditioning, grinding, coating

- Measurement over a period of up to 24 hours

MEASURING PROCEDURE

-

1. Placement of the logger in the core layer of the wood based mat

2. Marking of the logger‘s position on the mat edge

3. Continuous measurement of temperature while running through the hot press

4. Synchronize measurement with press inlet and outlet

APPLICATIONS

-

- Particleboard, OSB, MDF manufacturers

- Original equipment manufacturers (OEM)

- Research institutes

- Insulating material manufacturers (up to 125 °C)

- Glue producers

TECHNICAL DATA

-

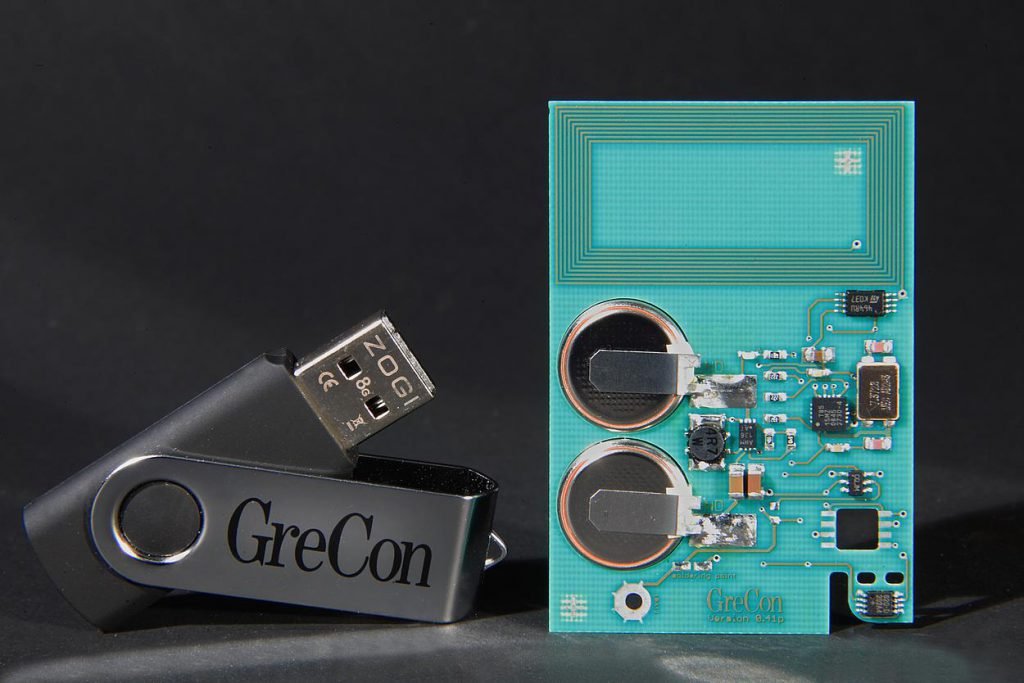

Dimensions (lxwxh) 69mm x 45mm x 2.5mm Measuring process programmable (> 0.25s) Thickness of the panel min. 10mm Battery life min. 24 hours after activation -

Operating temperature 0°C up to +125°C Measurement accuracy +-2°C Resolution 0.0625°C -

Measuring range 0 up to 580 kPa (above atmospheric pressure) Resolution 1.3 kPa -

Operating system Windows 10 pro Dimensions, including protective rubber (lxwxh) approx. 268.5 mm x 185.5 mm x 9 mm Weight approx. 700g Colour display 10.8“ (1920 x 1280) -

- USB

TURN KEY PROJECTS SOLUTIONS