GreCon MM 6000

BENEFITS AT A GLANCE

-

- Extremely fast and precise moisture measurement

- Independent of density

- Fast and early detection of troubles

- Non-contact measurement of endless materials (MM 6000 VS)

- Continuous measurement of the moisture content of endless materials (MM 6000 VS)

- No influence by color and form of the material to be measured

- Long-time stability

- Contact (MM 6000) or non-contact (MM 6000 VS) measurement, depending on the customer’s requirements

- Suitable for continuous and discontinuous material flows

DESIGN OF THE SYSTEM

-

The MM 6000 series measuring systems provide precise measuring results. Measurement is conducted inline, independent of density, surface structure and colour of the material measured. Due to the deep penetration of the microwave field/signal into the product, the water, which is physically bound, is determined by the sensor‘s detuning and attenuation of the frequency of resonance.

Measurement is done either by contact of the material with the measuring head/sensor (MM 6000) or in a noncontact way by a slit sensor (MM 6000 VS). The non-contact measuring method is suitable for both continuous (MM 6000 VS) and non-continuous (MM 6000 VS LMS) material flows.

AREAS OF APPLICATION

-

An MM 6000 (up to 70 °C) and MM 6000 XT (< 140 °C) is preferred in this position. At the dryer outlet after the rotary valve in the drop chut, the moisture values can be used to control and regulate the dryer. References exist for particle board and MDF-applications.

-

The use of a moisture analyzer in or after the forming line gives final data about the moisture of the spread chip or fiber mat. Control of upstream processes of chip or fiber processing are possible.

-

The finished panels are checked inline for the predetermined moisture values. Thus, it is ensured that the panels are supplied to the end customers with the right moisture. MM 6000 VS is preferred in this position.

-

The material (e.g. MDF, OSB or chips) passes equaly the sensor. The preferred sensor is MM 6000.

Woodprocessing Industry (e.g. furniture, veneer, parquet, panel)

-

depending on the thickness of the produced material the preferred sensor is either MM 6000 VS or MM 6000VS XL

Food Industry

-

preferred sensor is either MM 6000 or MM 6000 XT

Paper / Foil Industry

-

preferred sensor is MM 6000 VS LMS; for automatic calibration the sensor leaves the production lane on its own

Pet Food Industry

-

preferred sensor is either MM 6000 or MM 6000 XT

Tobacco Industry

-

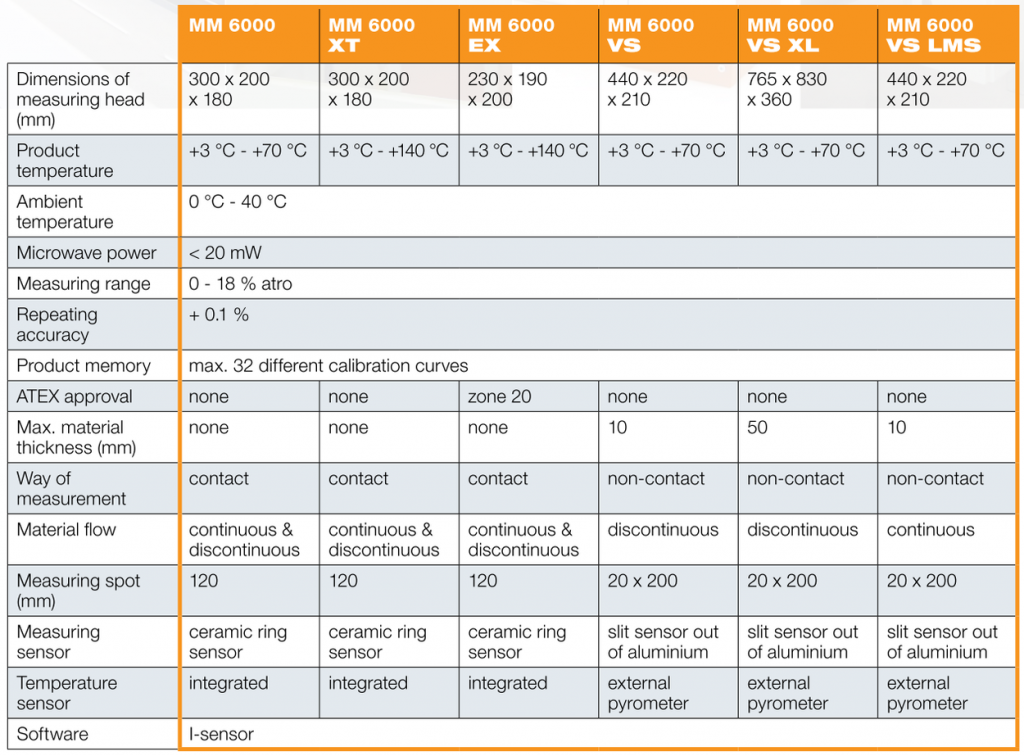

Supply voltage see chart homepage Frequency see chart homepage Mains type see chart homepage Power consumption see chart homepage Compressed air supply see chart homepage Compressed air consumption see chart homepage -

Places of installation (other places of installation on request) see chart homepage Ambient temperature see chart homepage Relative humidity see chart homepage Protection class see chart homepage -

Type of material see chart homepage Material/panel size see chart homepage Material/panel length see chart homepage Material/panel thickness see chart homepage Transport speed see chart homepage Product temperature see chart homepage -

Number see chart homepage Measuring process (see product finder) see chart homepage Measuring range see chart homepage Repeat accuracy (in case of constant environmental conditions) see chart homepage Resolution (diameter of the measured spot) see chart homepage Min. detectable default size see chart homepage Minimum distance between two sensors see chart homepage Measuring speed see chart homepage -

The systems provide analog outputs (4 to 20 mA) for the visualisation of moisture content and temperature as well as for data transfer to a PLC/software. Furthermore, they are equipped with digital outputs for alarming upon exceeding of limiting values as well as digital inputs for measurement control.