GreCon SUPERSCAN SPM/L

Continuous objective sorting of coated panels with the surface inspection system SUPERSCAN SPM/L

Slim and powerful. With an installation depth of only 200 mm in direction of production, the new SUPERSCAN finds its place in every production line of wood-based panels. This small installation depth has become possible thanks to an innovative LED lighting concept. The SUPERSCAN SPM/L replaces the manual inspection of panel-shaped materials. This continuous and constant quality control ensures consistent panel quality. The SUPERSCAN SPM/L inspects the surface decor of each panel inline. Defect reports and statistical data allow detailed conclusions of the upstream production process and the product quality. Not only sorting, but the entire production process can be optimised.

- Furniture board: Virtual grid of the complete panel using cut-to-size sections is possible.

- Flooring: Defect allocation of individual planks and marking on the complete panel for one-sided inspection.

BENEFITS AT A GLANCE

DESIGN OF THE SYSTEM

The basic construction of the measuring system is a solid, closed frame. Doors allow easy access to individual measuring components. Slight overpressure provides optimum measuring conditions while cooling the light source.

MEASURING METHOD

Each panel is inspected by a camera system, inspecting either one or both surfaces. Defective areas are detected where the surface decor differs from the normal (perfect) surface. Each defective area is classified (typified) in light and dark defects. The parameters for quality allocation and the sorting criteria are easily adjustable.

The system is self-learning. It can distinguish between new and known decors. For known surfaces, the stored image data is simply called up from a database at the beginning of a new order. The system is immediately operational.

For new decors, two successive panels are compared. If the deviations between the panels are smaller than the preset tolerance limits, these panels will be used as samples. All following panels are compared with the new decor. This procedure is very easy and takes only a few minutes so that any number of different surfaces can be stored within a short time period.

Defects on the surface of each panel are determined and, if desired, displayed on the monitor. Quality is determined by evaluating data, such as defect type, size and position. The sorting station is automatically triggered by the quality definition

SOFTWARE FEATURES

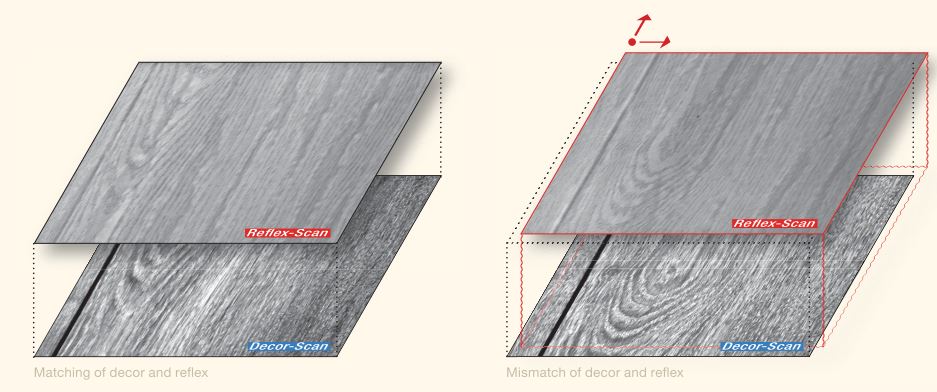

MONITORING OF THE SYNCHRONISED GRAIN WITH THE REFLEX MODULE

FURTHER INFORMATION