Hardening shops

Fire protection for hardening shops

Hardening of steel holds numerous risks of fire. The hardening process starts with the heating of metallic parts to temperatures of up to 900 °C. For hardening, the melting charge is dipped into a 70 °C warm oil bath

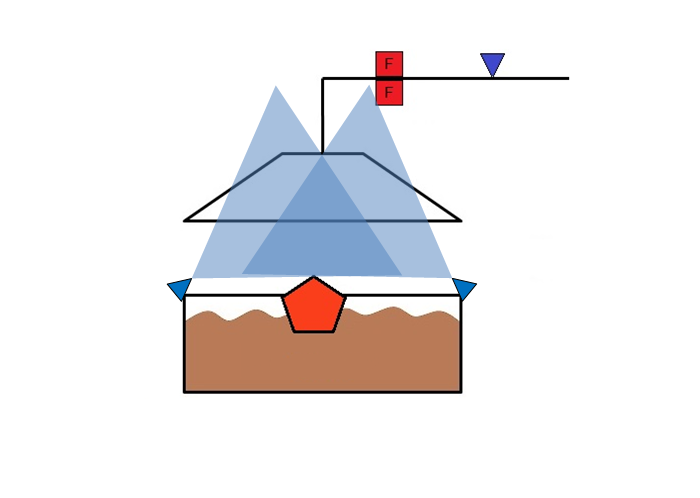

to obtain the desired chemical and physical characteristics.The hardening process in open oil basins holds a high risk of fire. With the high temperature of hot parts, the oil gas on the oil bath surface ignites. If the parts cannot be completely dipped due to process troubles, there is a risk of the fire spreading in the quenching chamber and to adjoining plant areas.

POTENTIAL DANGER

PROTECTION CONCEPT

TURN KEY PROJECTS SOLUTIONS