Preventive Fire Protection for Belt dryer applications

Risks and Protection Concept

Modern drying systems are ubiquitous in process engineering. The applications range from the food industry to the pulp and paper industry, pellet production and the wood-based materials industry. The basic principle is always similar: Bulk solids are transported into the dryer with moisture that is too high for the next processing step. The material is flowed through with hot or warm air.

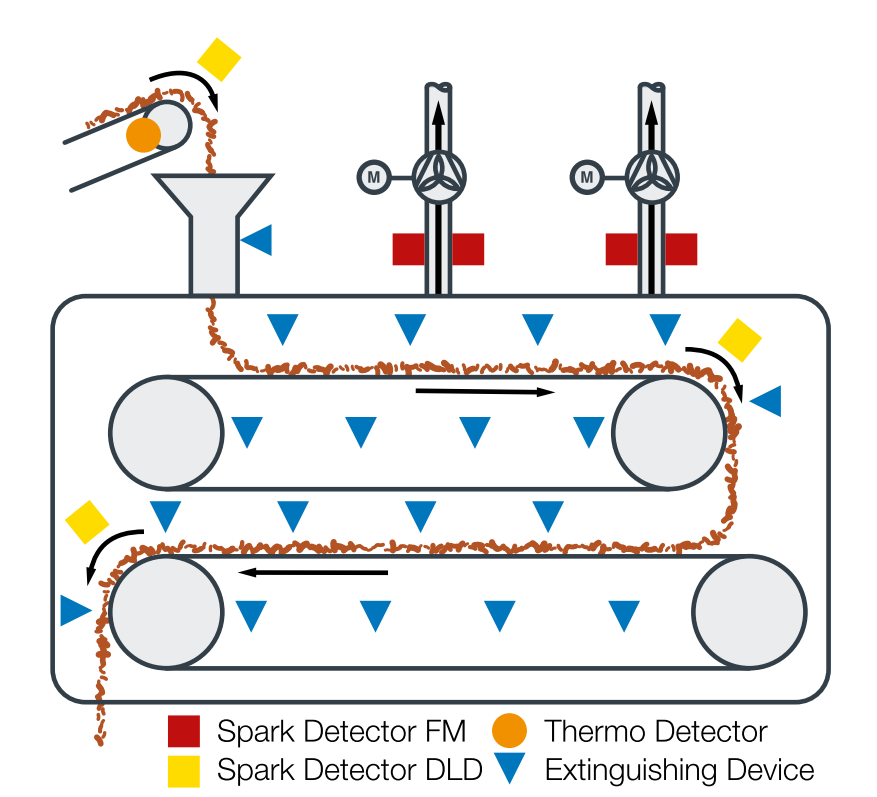

In almost all o.g. Application areas are subject to the same risks. Very dry or overheated material carries a constant risk of fire in the dryer. The edge areas of the dryer belt are particularly at risk. Also fallen down material on the dryer floor is a danger.

The fire risks in the belt dryer are manifold. The material to be dried loses moisture at the end of the dryer and is therefore easily flammable. Fire risks must be identified early on and rendered harmless, before a damage event occurs. If, for example, due to a system error, a belt stop or material deposits occur, the material is overdried. The material that is too dry is highly flammable and may ignite due to high process temperatures, friction or registered ignition initiation.

POTENTIAL DANGER IN BELT DRYER

PROTECTION CONCEPT FOR BELT DRYER

BENEFITS AT A GLANCE