PROCESS Opt

Qualitative and quantitative determination of properties and ingredients in raw or processed material

The ProcessOPT products are especially designed for the inline process analysis.Qualitative and quantitative determination of properties and ingredients in raw or processed material are possible with the ProcessOPT products. All ProcessOPT products measure the water and ash/mineralic content. With further calibrations sets measurements of additional parameters such as the calorific value, lignin, wood type and many more parameters are possible.

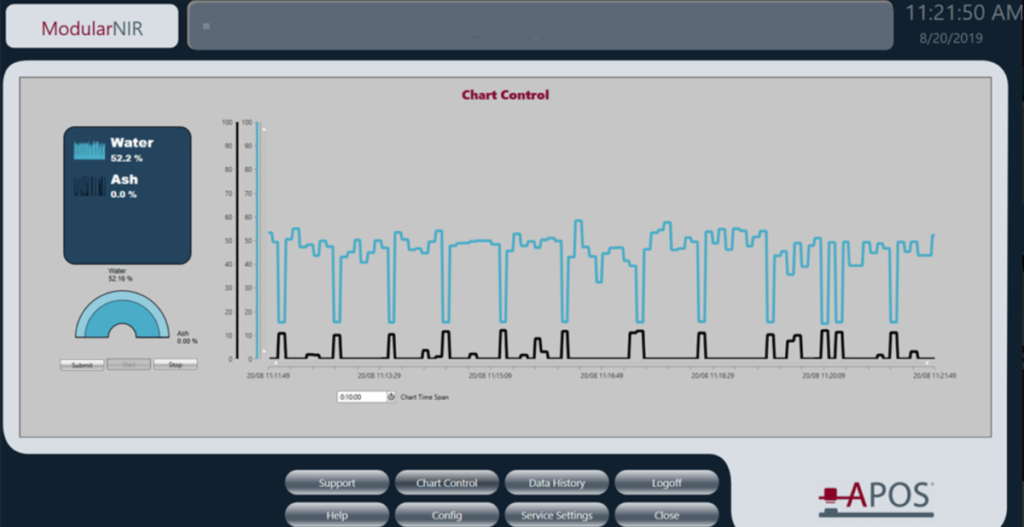

ModularNIR: Measurement of moisture and other parameters in wood-based panel production.

WoodClassifier: Classification of wood type and ratio for Glue Reduction in MDF- and particle board production.

BoilerControl: Determination of calorific value, water and ash content for biomass plants for a higher degree of plant automation and higher efficiency.

ResinReducer: Determining the resin content of the fibers or particles to adjust the glue addition during the process for improving the production process.

N-Alyzer: Measurement of nitrogen content of raw chips before or/and after the dryer. Determination of recycling wood share (Glued fraction) during the production process.

BENEFITS AT A GLANCE

DESIGN OF THE SYSTEM

All ProcessOPT products works with an standard measuring setup consisting of up to two NIR measuring heads, the central spectrometer unit (CSU) and an evaluation computer with the product software. Two different measuring heads are available. The contact measuring head and the distance measuring head, which can be used if no direct contact with the material to be measured is possible (e.g. measurement of wood chips on a conveyor belt).

The visualization of the measured data is done on the measured data computer. The measured values can optionally be exported directly to a customer control system. 4…20 mA outputs are available for this purpose.

MEASURING METHOD

The basic technology for the measurements is near-infrared spectroscopy (NIR spectroscopy). The optical method measures the reflection/absorption of a sample during irradiation in the near infrared range. The spectroscopic-physical properties of a sample are used. For this purpose, the sample is irradiated with light in the NIR range. The light penetrates into the sample and is partially absorbed there – depending on the chemical composition. Depending on which substances are present, part of the energy is absorbed in a very specific wavelength range and part is reflected. A spectrum is then created in the spectrometer from the backscattered light. With the aid of mathematical models, information about the composition of the sample can be obtained from the spectrum.

SOFTWARE FUNCTIONS AND VISUALISATION

APPLICATION

TECHNICAL DATA