RECEIVING OPT

Material reception for wood-based panel industry and for thermal use

The ReceivingOPT products are especially designed for the material reception. Material acceptance, quality assurance and billing on a bone dry basis of roundwood, wood chips, sawdust, recycling wood.

All ReceivingOPT products measure the water and ash content and additionally the calorific value of the delivered material. All measured data can be exported to excel, databases or to your ERP system for further processing and billing.

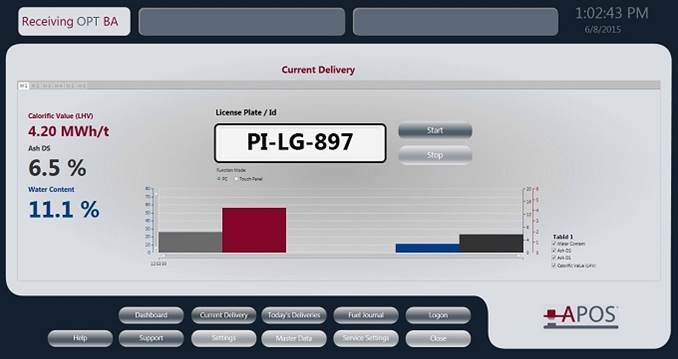

ReceivingOPT BA: Online analysis of biomass instantly upon delivery without sample taking and in real time.

ReceivingOPT BA-T 2.0: Sample analysis during the material reception in thermal use of wood. Analysis of water content, ash content and calorific value. It is the ideal solution, when there is no dumping site/bunker available for a fixed installation of ReceivingOPT BA

ReceivingOPT BA-T 300: Especially designed for round wood sampling as present in nearly all woodworking companies worldwide. Reliable values for moisture and ash in 2,5 minutes. Ideal for the analysis of small samples of about 200-800g.

BENEFITS AT A GLANCE

DESIGN OF THE SYSTEM

All ReceivingOPT products works with an standard measuring setup consisting of up to two NIR measuring heads, the central spectrometer unit (CSU) and an evaluation computer with the product software.The sensors of the ReceivingOPT BA were installed directly to the dumping site or bunker where the material will dumped through the truck. The ReceivingOPT BA-T 2.0 and ReceivingOPT BA-T 300 are stand-alone products which have the NIR measuring heads, the central spectrometer unit (CSU) and the computer inside the housing of the system. In the ReceivingOPT BA-T 2.0 the material is put in by the user and the system brings the material with a integrated screw conveyor over the NIR measuring head. The ReceivingOPT BA-T 300 has a integrated shredder which can shrink bigger particles of the material. The material sample will put into the system from the user. The System comes with calibrations for water content, ash content and calorific value. The standard calibrations are for the use with non-frozen materials. Calibrations for frozen materials available. Additionally, data can be exported as an Excel file or to a third party system using the data interface. It is also possible to integrate to an existing weighing software of e.g. a truck scale, in order to import the values into the BA-T system to complete the entry in the goods receipt book. Additionally, the systems can automatically send the daily journal to an e-mail distribution list.

MEASURING METHOD

ReceivingOPT BA:

- While the truck is on the truck scale, it is registered in the APOS system. With integration of the truck scale in the APOS system, the weighing data is automatically transferred to System.

- During unloading the fuel is transported over the sensor. Measurement values are generated every 0.9 seconds, which sums up to almost 1000 individual measurements per truck.

- The material is analyzed in real time regarding e.g. its water and ash content and calorific value. The analysis is performed in the central spectrometer unit (CSU).

- All data can be exported to excel or your ERP for further processing. APOS has realized various ERP interfaces and if necessary an individual interface can be created

ReceivingOPT BA-T 2.0:

- The material is unloaded by truck at different locations in the storage yard.

- The operator takes a sample of approximately 8 litres from the pile. The sample is put into the analysis container of the system and the system is started with the push of a button.

- Measured values as well as the moving average will be displayed graphically to the operator during the analysis, which takes approximately 3 minutes.

- All data can be exported to excel or your ERP for further processing. APOS has realized various ERP interfaces and if necessary an individual interface can be created

ReceivingOPT BA-T 300:

- The truck delivers roundwood to your plant.

- Chip samples created with a chainsaw at the round wood reception terminal as usual.

- Objective and validated data for moisture, ash and more at the round wood sampling station in 2,5 minutes.

- All data can be exported to excel or your ERP for further processing.

SOFTWARE FUNCTIONS AND VISUALISATION

APPLICATION

ReceivingOPT BA

ReceivingOPT BA-T 2.0N

ReceivingOPT BA-T 300:

TECHNICAL DATA