SYN TEST PTM

Automated test laboratory for the wood-based panel industry

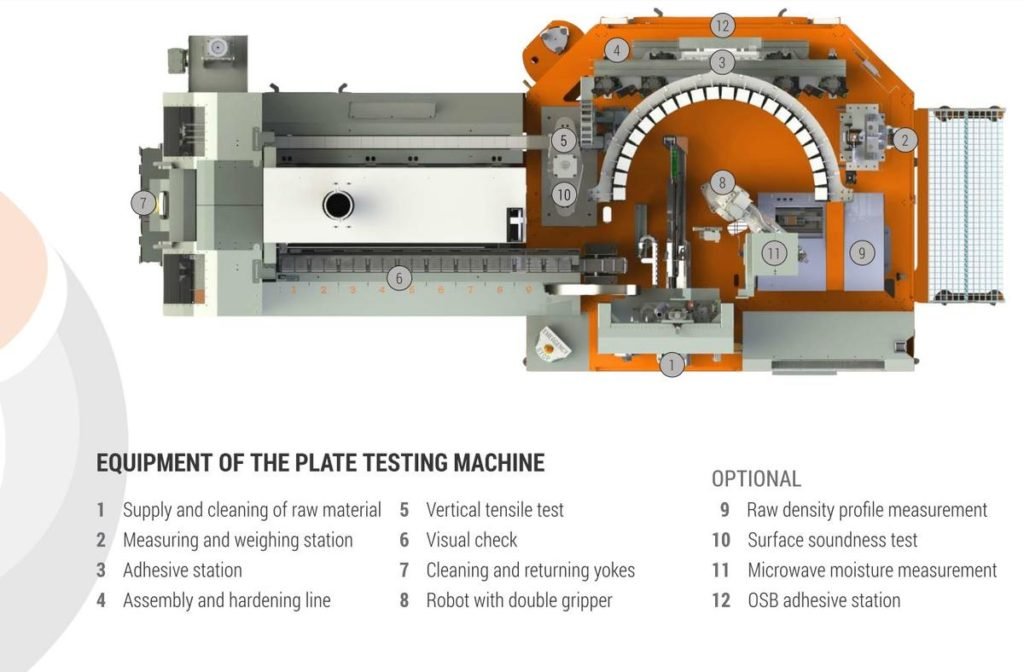

The SYN TEST PTM (Plate Testing Machine) system is used for automated transverse tensile testing as well as automated lift resistance testing of wood-based panels.

A big advantage is the repeatability of the tests. The adhesive quantity and pattern, curing time, contact pressure and centering are reproducible in contrast to the manual / semi-automated test. A deployment is possible around the clock, 7 days a week and an immediate transfer of the results into the production is possible. The operation is simple and is also possible by non-laboratory personnel. An increased production speed as well as a reduced scrap lead to a short payback period of the testing laboratory.

BENEFITS AT A GLANCE

DESIGN OF THE SYSTEM

The test system can also be equipped optionally with an automated raw density profile measuring system and an automated micro-wave moisture measurement. The two laboratory measuring units GreCon DAX 6000 and MM 6000 from Döscher can be easily integrated into the test system and also equipped automatically

MEASURING METHOD

Ceramic transmitters are installed below the material flow. The ultrasonic signal generated by the transmitters penetrates the material and is received and evaluated by the receivers that are installed above the material flow. An attenuation of the received ultrasonic energy is registered as a deviation from the nominal value and indicates a possible weak point.

In order to protect the sound quality against disturbing influences, such as reflections, the wanted signal is protected by protection curtains.

In order to obtain good measuring results, the measuring conditions should be the same for all channels. The operator can check the function of the inspection channels and re-adjust, if necessary, by an electronic adjustment that can be conducted in panel gaps during the production

SOFTWARE FUNCTION AND VISUALISATION

APPLICATIONS

TECHNICAL DATA